Introduction to Insulation Foil

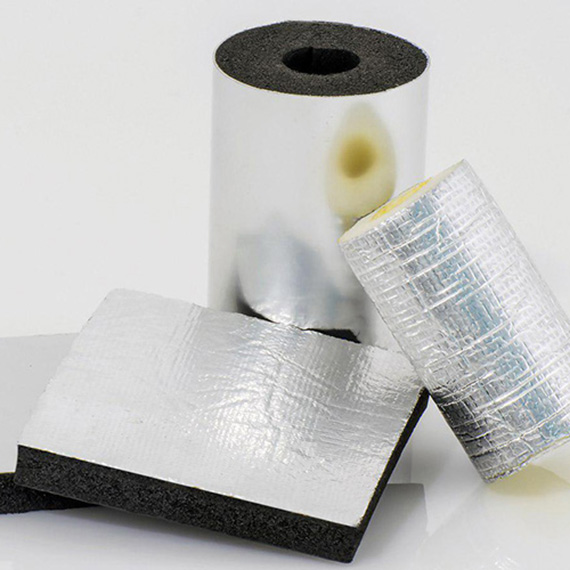

Insulation foil is a thin layer typically made of metals like aluminum, designed to reduce or control the transfer of heat, sound, and moisture in buildings, appliances, and various systems. These foils act as effective barriers against thermal exchange, especially in environments where temperature regulation and energy efficiency are essential.

Structure and Composition

Insulation foil is usually made from thin aluminum sheets, which are ideal due to aluminum’s reflective properties. They are often combined with other insulating layers like foam or fibers for enhanced thermal performance. In some cases, composite materials such as polyethylene or polyester are used.

Types of Insulation Foils

-

Single-layer aluminum foil: Common in residential and industrial thermal insulation.

-

Multi-layer composite foil: Aluminum combined with polyethylene foam or fiberglass for high-performance applications.

-

Thermal barrier foils: Used for preventing heat transfer in walls, ceilings, and floors.

Applications and Benefits

-

Energy savings: Maintains indoor temperatures and reduces the need for HVAC systems.

-

Thermal and acoustic insulation: Blocks heat and noise transmission.

-

Moisture resistance: Prevents mold, mildew, and material degradation.

-

UV protection: Extends the lifespan of building materials.

-

Easy installation: Lightweight and does not require complex tools.

Industrial Uses

-

Construction: Wall, ceiling, and floor insulation.

-

Automotive: Thermal protection for engines and HVAC systems.

-

Electronics: Heat shielding for electronic components.

-

Plumbing: Insulation for hot water pipes and heating systems.

Conclusion

With its unique properties, insulation foil plays a vital role in energy efficiency, environmental protection, and comfort across many sectors. It is a cost-effective and sustainable solution for modern insulation needs.

Technical Specifications:

-

For composite panels and waterproofing membranes (isogam)

-

Temper: HO

-

Alloys: 1235 – 8111 – 8011

-

Thickness: 14–60 microns

-

Width (mm): Up to 1600